How To Remove Walmart Starter Earrings

A slotted or "flat-bract" screwdriver | |

| Other names | Turnscrew |

|---|---|

| Classification | Paw tool |

| Types | Come across List of spiral drives |

| Related | Hex cardinal Wrench |

A screwdriver is a tool, manual or powered, used for driving screws. A typical simple screwdriver has a handle and a shaft, ending in a tip the user puts into the spiral caput before turning the handle. This form of the screwdriver has been replaced in many workplaces and homes with a more modern and versatile tool, a power drill, as they are quicker, easier, and can likewise drill holes. The shaft is usually made of tough steel to resist bending or twisting. The tip may be hardened to resist wear, treated with a dark tip coating for improved visual contrast between tip and screw—or ridged or treated for additional 'grip'. Handles are typically woods, metallic, or plastic[1] and unremarkably hexagonal, foursquare, or oval in cross-department to improve grip and prevent the tool from rolling when set down. Some manual screwdrivers have interchangeable tips that fit into a socket on the end of the shaft and are held in mechanically or magnetically. These often have a hollow handle that contains diverse types and sizes of tips, and a reversible ratchet action that allows multiple full turns without repositioning the tip or the user'due south hand.

A screwdriver is classified past its tip, which is shaped to fit the driving surfaces—slots, grooves, recesses, etc.—on the corresponding screw head. Proper utilize requires that the screwdriver'southward tip engage the head of a spiral of the same size and type designation as the screwdriver tip. Screwdriver tips are available in a wide diversity of types and sizes (Listing of spiral drives). The 2 about common are the simple 'blade'-type for slotted screws, and Phillips, generically called "cross-recess", "cross-head", or "cross-point".

A broad variety of power screwdrivers ranges from a simple 'stick'-blazon with batteries, a motor, and a tip holder all inline, to powerful "pistol" type VSR (variable-speed reversible) cordless drills that too function as screwdrivers. This is particularly useful equally drilling a pilot pigsty before driving a screw is a mutual performance. Special combination drill-driver bits and adapters let an operator rapidly alternate between the 2. Variations include impact drivers, which provide two types of 'hammering' forcefulness for improved performance in certain situations, and "correct-angle" drivers for utilize in tight spaces. Many options and enhancements, such as congenital-in bubble levels, high/depression gear selection, magnetic screw holders, adaptable-torque clutches, keyless chucks, 'gyroscopic' control, etc., are available.

History [edit]

The earliest documented screwdrivers were used in the belatedly Eye Ages. They were probably invented in the late 15th century, either in Germany or France. The tool's original names in German and French were Schraubenzieher [2] [3] [four] (screwpuller) and tournevis (turnscrew), respectively. The first documentation of the tool is in the medieval Housebook of Wolfegg Castle, a manuscript written old between 1475 and 1490.[5] These earliest screwdrivers had pear-shaped handles and were made for slotted screws (diversification of the many types of screwdrivers did not emerge until the Gilded Age). The screwdriver remained camouflaged, yet, as evidence of its beingness throughout the next 300 years is based primarily on the presence of screws.

Screws were used in the 15th century to construct spiral-cut lathes, for securing breastplates, backplates, and helmets on medieval jousting armor—and eventually for multiple parts of the emerging firearms, particularly the matchlock. Screws, hence screwdrivers, were non used in total combat armor, nigh likely to give the wearer freedom of movement.[ further explanation needed ]

The jaws that concur the pyrites inside wheellock guns were secured with screws, and the demand to constantly supercede the pyrites resulted in a considerable refinement of the screwdriver. The tool is more than documented in France, and took on many shapes and sizes, though all for slotted screws. There were big, heavy-duty screwdrivers for building and repairing large machines, and smaller screwdrivers for refined cabinet work.

The screwdriver depended entirely on the spiral, and it took several advances to make the screw easy enough to produce to become pop and widespread. The about popular door swivel at the time was the barrel-swivel, but it was considered a luxury. The barrel-hinge was handmade, and its abiding motility required the security of a screw.

Screws were very hard to produce earlier the Starting time Industrial Revolution, requiring the manufacture of a conical helix. The brothers Job and William Wyatt plant a way to produce a screw on a novel machine that offset cut the slotted head, then cutting the helix. Though their business ultimately failed, their contribution to low-cost manufacturing of the screw ultimately led to a vast increase in the screw and the screwdriver's popularity. The increase in popularity gradually led to refinement and eventually diversification of the screwdriver. Refinement of the precision of screws also significantly contributed to the blast in product, generally by increasing its efficiency and standardizing sizes, important precursors to industrial industry.

Canadian P.L. Robertson, though he was not the commencement person to patent the idea of socket-caput screws, was the first to successfully commercialize them, starting in 1908. Socket screws apace grew in popularity, and are still used for their resistance to wear and tear, compatibility with hex keys, and ability to stop a power tool when fix. Though immensely pop, Robertson had problem marketing his invention to the newly booming auto industry, for he was unwilling to relinquish his patents.

Meanwhile, in Portland, Oregon, Henry F. Phillips patented his own invention, an improved version of a deep socket with a cruciform slot, today known as the Phillips Screw. Phillips offered his spiral to the American Screw Company, and after a successful trial on the 1936 Cadillac, it quickly swept through the American auto industry. With the Industrial Revival at the end of the Great Depression and the upheaval of World State of war 2, the Phillips spiral quickly became, and remains, the most pop screw in the world. A main attraction for the screw was that conventional slotted screwdrivers could besides be used on them, which was not possible with the Robertson Screw.

Gunsmiths still call a screwdriver a turnscrew, under which proper name information technology is an important part of a set up of pistols. The name was common in earlier centuries, used by cabinetmakers, shipwrights, and perhaps other trades. The cabinetmaker'southward screwdriver is one of the longest-established handle forms, somewhat oval or ellipsoid in cross-section. This is variously attributed to improving grip or preventing the tool rolling off the bench. The shape has been pop for a couple of hundred years. It is usually associated with a evidently head for slotted screws, but has been used with many head forms. Modern plastic screwdrivers utilise a handle with a roughly hexagonal cross-section to achieve these aforementioned 2 goals, a far cry from the pear-shaped handle of the original 15th-century screwdriver.[ according to whom? ]

Handle [edit]

"Perfect Handle" screwdrivers

The handle and shaft of screwdrivers accept changed considerably over time. The design is influenced by both purpose and manufacturing requirements. The "Perfect Blueprint Handle"[ farther explanation needed ] screwdriver was first manufactured by Hd Smith & Company, which operated from 1850 to 1900. Many manufacturers adopted this handle blueprint. At the fourth dimension, the "flat bladed" screw type was prevalent and was the fastener with which they were designed to be used. Another popular design was composed of drib-forged steel with riveted woods handles.

Screwdriver with rubber handle

The shape and material of many modern screwdriver handles are designed to fit comfortably in the user's manus, for user comfort and to facilitate maximum control and torque. Designs include indentations for the user's fingers, and surfaces of a soft fabric such as thermoplastic elastomer to increase comfort and grip. Composite handles of rigid plastic and safe are likewise mutual. Many screwdriver handles are not smooth and oftentimes non round, but have flats or other irregularities to improve grip and to prevent the tool from rolling when on a apartment surface.

Some screwdrivers accept a brusk hexagonal section at the meridian of the blade, adjacent to the handle, then that a band spanner or open wrench can exist used to increment the practical torque. Another pick are "cabinet" screwdrivers which are made of flat bar stock and while the shaft may be rounded, will take a large flat section adjacent to the handle which a wrench (oftentimes an adaptable) may be used on for boosted leverage. The offset screwdriver has a handle set at right angles to the pocket-size blade, providing access to narrow spaces and giving extra torque.

Drive tip [edit]

Screwdrivers come in a large range of sizes to conform diverse screws—from tiny jeweller'southward screwdrivers upwardly. A screwdriver that is non the right size and blazon for the screw may damage the spiral in the process of tightening it.

Some screwdriver tips are magnetic, and then that the screw (unless non-magnetic) remains attached to the screwdriver without requiring external force. This is particularly useful in small screws, which are otherwise very difficult to endeavour to handle. Many screwdriver designs have a handle with a detachable tip (the function of the screwdriver that engages the screw), called bits as with drill bits. This provides a set of one handle and several bits that can drive a multifariousness of screw sizes and types.

Drive types [edit]

-

A jeweler's screwdriver

-

Screwdriver with magnetic tip

-

A set of "secure" or otherwise less mutual screwdriver bits, including secure Torx and secure hex or "allen" variants.

-

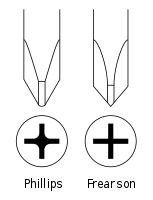

Comparison of Phillips and Frearson spiral heads

-

A variety of Robertson sizes

-

Phillips and Pozidriv compared.

The tool used to drive a slotted spiral head is chosen a standard, common blade, flat-blade, slot-head, directly, apartment, flat-tip,[6] or "flat-head"[vii] screwdriver. This concluding usage can be confusing, because the term flat-head also describes a screw with a flat pinnacle, designed to install in a countersunk hole. Furthermore, the term implies that a screwdriver has a "head"; information technology does not. Such a flat-headed screw may have a slotted, cantankerous, square recessed, or combination head. Earlier the evolution of the newer bit types, the flat-blade was called the "Mutual-Blade", because it was the most common i. Depending on the application, the name of this screwdriver may differ. Within the automotive/heavy electric industries, it is known as a "flat caput screwdriver";[8] within the avionics and mining industries, it is known equally a "standard screwdriver".[ix] Though there are many names, the original device from 1908 was known as a "flat-head screw turner".[ citation needed ]

Among slotted screwdrivers, variations at the blade or bit end involve the profile of the blade every bit viewed face-on (from the side of the tool). The more common type is sometimes called keystone, where the blade profile is slightly flared before tapering off at the end, which provides extra stiffness to the workface and makes it capable of withstanding more torque. To maximize access in space-restricted applications, the cabinet variant screwdriver blade sides are directly and parallel, reaching the stop of the bract at a correct angle. This design is likewise frequently used in jeweler'south screwdrivers.

Many textbooks and vocational schools instruct mechanics to grind down the tip of the blade, which, due to the taper, increases its thickness and consequently allows more precise engagement with the slot in the screw. This approach creates a set of graduated slotted screwdrivers that fit a item spiral for a tighter date and reduce screw head deformation. Yet, many improve-quality screwdriver blades are already consecration-hardened (surface heat-treated), and tip grinding after manufacture compromises their durability. Thus, it is best to select a tip made to fit precisely to begin with, and avoid weakening the mill oestrus-treatment.

Phillips screwdrivers come in several standard sizes, ranging from tiny "jeweler's" to those used for automobile frame assembly—or #000 to #4 respectively. This size number is usually stamped onto the shank (shaft) or handle for identification. Each chip size fits a range of screw sizes, more or less well. Each Phillips screwdriver size also has a related shank bore. The commuter has a 57° point and tapered, unsharp (rounded) flutes. The #one and smaller bits come to a blunt indicate, simply the #ii and above have no indicate, but rather a nearly squared-off tip, making each size incompatible with the other.

The design is often criticized for its tendency to cam out at lower torque levels than other "cross head" designs, an effect caused past the tapered contour of the flutes which makes them easier to insert into the screw than other similar styles. In that location has long been a popular belief that this was really a deliberate feature of the design. Evidence is defective for this specific narrative and the characteristic is not mentioned in the original patents.[10] However, a subsequent refinement to the original design described in US Patent #2,474,994[11] [12] [13] describes this feature.

Robertson, also known as a square,[fourteen] or Scrulox [xv] screw drive has a foursquare-shaped socket in the spiral head and a foursquare protrusion on the tool. Both the tool and the socket take a taper, which makes inserting the tool easier, and also tends to help keep the screw on the tool tip without the user needing to concord it there. (The taper's earliest reason for being was to make the manufacture of the screws practical using cold forming of the heads,[16] just its other advantages helped popularize the drive.) Robertson screws are commonplace in Canada, though they accept been used elsewhere,[17] and have become much more than common in other countries in recent decades. Robertson screwdrivers are easy to use one-handed, because the tapered socket tends to retain the screw, even if it is shaken.[17] They also allow for the utilise of angled spiral drivers and trim head screws. The socket-headed Robertson screws are cocky-centering, reduce cam out, stop a power tool when set, and can exist removed if painted over or quondam and rusty.[17] In industry, they speed up product and reduce product damage. One of their first major industrial uses was the Ford Motor Visitor'southward Model A & Model T product. Henry Ford establish them highly reliable and saved considerable production time, merely he couldn't secure licensing for them in the United states, and so he express their use solely to his Canadian segmentation. Robertson-head screwdrivers are available in a standard range of tip sizes, from 1.77mm to 4.85mm.

Reed and Prince, also called Frearson, is another historic cross-head screw configuration. The cross in the spiral head is sharper and less rounded than a Phillips, and the scrap has 45° flukes and a sharper, pointed cease. Also, the Phillips spiral slot is not every bit deep every bit the Reed and Prince slot.[xviii] [19] [twenty] In theory, different size R&P screws fit any R&P bit size.[21]

Pozidriv and the related Supadriv are widely used in Europe and most of the Far East.[22] While Pozidriv screws take cross heads like Phillips and are sometimes idea effectively the same, the Pozidriv design allows higher torque application than Phillips. It is often claimed that they can use more torque than any of the other commonly used cross-head screwdriver systems, due to a circuitous fluting (mating) configuration.

Japanese Industrial Standard (JIS) cross-head screwdrivers are still another standard, often inaccurately chosen Japanese Phillips. Compatible screw heads are ordinarily identifiable past a single depressed dot or an "X" to one side of the cross slot. This is a screw standard throughout the Asia market and Japanese imports. The driver has a 57° signal with a apartment tip.[23]

Many modern electric appliances, if they contain screws, use screws with heads other than the typical slotted or Phillips styles. Torx is ane such design that has become widespread. It is a spline tip with a respective recess in the screw head. The principal cause of this trend is manufacturing efficiency: Torx screwdriver tips do non slip out of the fastener as easily as would a Phillips or slotted driver. (Slotted screws are rarely used in mass-produced devices, since the driver is not inherently centered on the fastener.)

Non-typical fasteners are commonplace in consumer devices for their power to make disassembly more difficult, which is seen as a benefit for manufacturers simply is considered a disadvantage by users than if more common caput types were used. In microwave ovens, such screws deny casual access to the loftier-power kilovolt electric components, which are very dangerous.

However, Torx and other drivers take become widely bachelor to the consumer due to their increasing use in the industry. Some other styles fit a three-pointed star recess, and a five-lobed spline with rounded edges instead of the square edges of the Torx. This is called a Pentalobe.

Specialized patterns of security screws are also used, such as the Line Caput (LH) style by OSG Organization Products, Japan, as used in many Nintendo consoles, though drivers for the more common security heads are, again, readily available. Another blazon of security head has smooth curved surfaces instead of the slot edges that would permit loosening the screw; information technology is found in public residuum room privacy partitions, and cannot be removed by conventional screwdrivers.

Variations [edit]

Torque screwdrivers [edit]

Screwdrivers are available—manual, electric, and pneumatic—with a clutch that slips at a preset torque. This helps the user tighten screws to a specified torque without damage or over-tightening. Cordless drills designed to use as screwdrivers oft have such a clutch.

Powered screwdrivers [edit]

A rechargeable battery-powered electric screwdriver.

Interchangeable bits permit the utilize of powered screwdrivers, commonly using an electric or air motor to rotate the fleck. Cordless drills with speed and torque command are ordinarily used equally power screwdrivers.

Driving a screw with a cordless drill

How to use a cordless drill equally a powered screwdriver

Ratcheting screwdrivers [edit]

![]()

Stanley Yankee No 130A, spiral or ratchet screwdriver

Some manual screwdrivers have a ratchet activity whereby the screwdriver blade locks to the handle for clockwise rotation, but uncouples for counterclockwise rotation when set for tightening screws—and vice versa for loosening.

Screw ratchet spiral drivers, often colloquially called Yankee screwdrivers (a brand name), provide a special mechanism that transforms linear motion into rotational motion. Originally the "Yankee" proper noun was used on all tools sold by the North Brothers Manufacturing Company but later, after Stanley purchased the company, information technology became synonymous with simply this type of screwdriver. The user pushes the handle toward the workpiece, causing a pawl in a screw groove to rotate the shank and the removable flake. The ratchet can be set up to rotate left or right with each push, or can be locked and then that the tool can be used similar a conventional screwdriver. One disadvantage of this pattern is that if the bit slips out of the screw, the resultant sudden extension of the spring may cause the bit to scratch or otherwise harm the workpiece.

One time very popular, versions of these spiral ratchet drivers using proprietary bits have been largely discontinued past manufacturers such every bit Stanley. Some companies now offer a modernized version that uses standard 1⁄4 -inch hex shank power tool $.25. Since a wide diverseness of drill bits are bachelor in this format, the tool can do double duty as a "push drill" or Persian drill.

Come across likewise [edit]

- List of screw drives

- Wheel and axle

References [edit]

Citations [edit]

- ^ "Screwdriver | tool". Archived from the original on 2022-12-19. Retrieved 2013-12-eighteen .

- ^ "Schraubenzieher « atlas-alltagssprache". Archived from the original on 2022-08-20. Retrieved 2021-08-09 .

- ^ "Franz Kafka: In der Strafkolonie". Archived from the original on 2022-08-09. Retrieved 2021-08-09 .

- ^ "Schraubenzieher". Archived from the original on 2022-08-06. Retrieved 2021-08-09 .

- ^ Rybczynski 2000, pp. 90–94.

- ^ Capotosto, Rosario (December 1996), "Screwdriver Basics", Popular Mechanics, 173 (12): 82–83, ISSN 0032-4558, archived from the original on 2022-02-16.

- ^ Review, Princeton (2004). Groovy the ASVAB . New York: Random Firm. p. 174. ISBN978-0-375-76430-one.

- ^ Chilton, G. (2001). Homebasics: the complete guide to running today's domicile . Barnes & Noble Books. p. eighteen. ISBN978-0-7607-2719-5 . Retrieved 27 September 2022.

- ^ Richards, A.J.; Stephenson, J.H. (1984). Avionic Navigation Systems Specialist. Avionic Navigation Systems Specialist. Extension Course Establish, Air University. p. 169. Archived from the original on 30 May 2022. Retrieved 27 September 2022.

- ^ Adler, Alexander (1998-05-18). Testing and Understanding Screwdriver Bit Wear (Master's thesis). Virginia Tech. hdl:10919/36701.

- ^ U.South. Patent 2,474,994

- ^ US 2474994, Tomalis, Joseph & American Spiral Company, "Screw Socket", published December 30, 1942, issued July 5, 1949

- ^ "US Patent #2,474,994 Claims, Page 7". Archived from the original on 2022-08-04.

- ^ Furniture Projects for the Deck and Lawn. Cambium Press. 2004. ISBN978-one-892836-17-5. Archived from the original on 2022-ten-11. Retrieved 2012-03-12 .

- ^ Robertson Inc. "Robertson Inc. - The Original Robertson Fastening Arrangement". Robertson Inc. primary site. Archived from the original on 2022-09-26. Retrieved 2011-09-28 .

- ^ Rybczynski 2000, pp. 79–81.

- ^ a b c Rybczynski 2000, pp. 85–86

- ^ "The Phillips screwdriver has most thirty° flukes and a edgeless end, while the Reed and Prince has 45° flukes and a sharper, pointed end." RECESSED www.tpub.com Archived 2009-04-08 at the Wayback Machine October 2022

- ^ Michael Uva (2010). The Grip Book. Taylor & Francis. ISBN978-0-240-81291-five. Archived from the original on 2022-07-07. Retrieved 2014-09-14 .

- ^ "Reed and Prince Screwdriver". www.scribd.com.

- ^ "Bits From MRO Tools". mrotools.com. Archived from the original on 2022-04-25.

The Frearson recess is designed and then that any size fleck will fit whatsoever size recess.

- ^ "When a Phillips is not a Phillips, step13: Posidriv". instructibles.com. Archived from the original on 2022-09-03.

- ^ "When a Phillips is not a Phillips, step10: JIS – Japanese Industrial Standard". instructibles.com. October 2022. Archived from the original on 2022-08-27.

Works cited [edit]

- Rybczynski, Witold (2000), Ane Proficient Turn: A Natural History of the Screwdriver and the Screw, Scribner, ISBN978-0-684-86729-eight, LCCN 00036988, OCLC 462234518. Various republications (paperback, e-volume, braille, etc).

External links [edit]

| | Look up screwdriver in Wiktionary, the gratis dictionary. |

How To Remove Walmart Starter Earrings,

Source: https://en.wikipedia.org/wiki/Screwdriver

Posted by: lewisliviss.blogspot.com

0 Response to "How To Remove Walmart Starter Earrings"

Post a Comment