How To Repair An Anti Siphon Valve

Anti-Siphon Valve Nuts

Managing your potable h2o menses is important, but perhaps even more important is managing your raw-water period. A critical component is the anti-siphon valve.

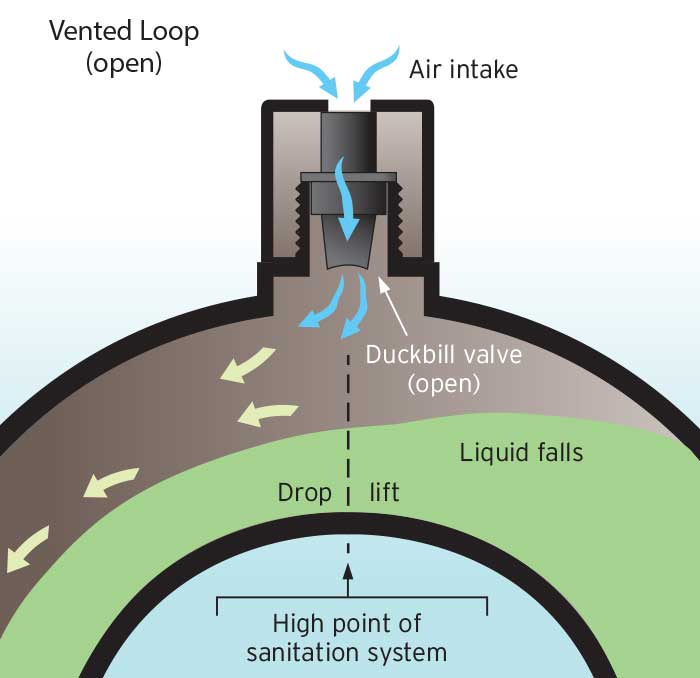

Most vented loops operate by allowing air into a passageway to break the siphon event. When catamenia from the pump stops, air is introduced through the duckbill valve. (Illustration: ©2018 Mirto Art Studio)

If you lot have an inboard engine or a marine head, chances are you accept an anti-siphon valve. If that anti-siphon valve stops working, its failure may destroy your engine or trash your boat with toilet discharge or sink the entire gunkhole. The practiced news is that anti-siphon valves are simple to inspect and like shooting fish in a barrel to maintain.

How It Works

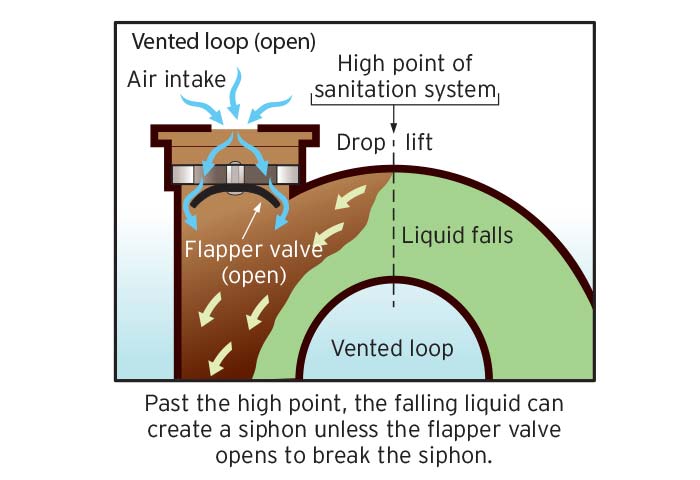

In your marine head, the anti-siphon valve works to help stop backflow of belch h2o into the head and then perhaps into the boat. A similar valve also works to help cease siphoning of water in the caput intake line when the head is below the maximum-heeled waterline. The anti-siphon valve should be installed above that point. Follow the head manufacturer'due south instructions with this.

Tip

Encrusted deposits effectually the outside surface of a vented loop is a sure sign that service is required.

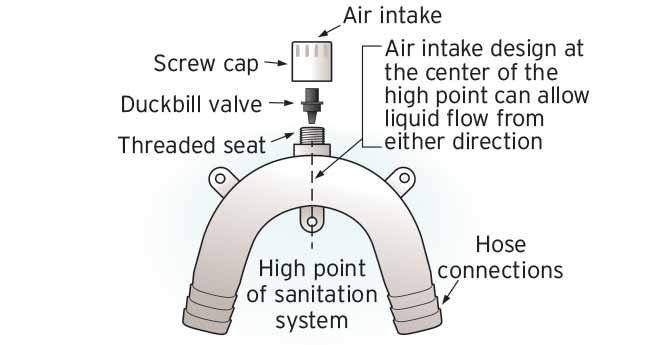

For the engine, the anti-siphon valve'south purpose is to stop raw cooling water from flowing into the exhaust manifold and through the exhaust ports in the block and and so down into the cylinders when the engine is shut down. It does this by providing a siphon break in an elevated loop at the highest point in the line, which is normally installed with the engine. It incorporates a valve that lets air into the hose to break the siphon effect when water stops flowing, and that keeps flowing water from spilling out of the hose. (Anti-siphon valve assemblies are sometimes referred to as "vented loops" because the valve is typically in a pipe assembly in a loop of hose.) These are not institute in all boats. At that place are other anti-siphon valves for fuel systems and other purposes. These are beyond the telescopic of this article.

Illustrations: ©2018 Mirto Fine art Studio

How To Fix And Maintain

Locate each 1 on your gunkhole. They usually live backside bulkheads or are stuck abroad in some corner of your engine space. A clue to their whereabouts is a hose leading to information technology and 1 going from it, with perhaps a smaller tube leading overboard. Information technology looks similar a looped pipe and is vented at the top.

1. Make sure in that location'south no weeping where the hoses join the looped pipe. This is indicated by salty eolith, green stain corrosion, and on the head hose, odour and perhaps other "stuff." If there is weeping, tighten the hose clamps. Information technology's best to remove the hose from each side of the pipe to make certain in that location's no corrosion or wear in the pipe nipples. This is particularly likely to occur with the caustic material coming from the caput and metal nipples. If the hoses leading to the loop are also tightly spaced, you may take difficulty doing this.

2. Remove the vent at the elevation of the looped piping and inspect it. This is done by removing the tube coming from the vent spout (if at that place is 1) and usually unscrewing the bronze, plastic, or PVC plumbing equipment at the top of the loop. Sometimes this is washed by unscrewing bolts that hold downwards the top to the vent.

Illustrations: ©2018 Mirto Art Studio

iii. The valve is ofttimes a rubberlike joker valve (also chosen duckbill valve) or a diaphragm valve. Each one is supposed to get to the open position when h2o flow ceases in society to let in air through the vent to avoid a siphon. When water is flowing (as by pumping the head or running the engine), the valve should exist closed to foreclose water from coming out of the air pigsty in the top of the vent.

4. For a joker valve, advisedly pull it out, taking care non to tear it. Check for tears or deformities. Oftentimes you'll need to replace information technology because it will exist stiff from calcium and other deposits, although you lot may be able to carefully make clean these off. Blowing with low-pressure air may help.

five. For a diaphragm valve: This is probable to be a flexible rubberlike membrane, which opens and closes over a stainless frame. The job volition probably require removal of some bolts to unseat the valve. Replace the valve if it is deformed, stiff, torn, or showing any other signs of working poorly. Sometimes just cleaning information technology will suffice. Clean the expanse in which it seats. A small castor may help, but ofttimes you lot tin can do information technology with just your fingers.

6. For other valves: Some valves accept a spring-loaded ball or flap on a hinge or other device or bladder designed for this purpose. Clean whatever spring and surfaces or other components according to manufacturer instructions. Cheque for malformation of components. Lubricate, but simply with a production recommended by the manufacturer. If at that place is any question, supercede the valve.

seven. If y'all have a vent tube leading overboard, information technology's disquisitional to see that this isn't clogged (such every bit by bugs), as this could take the aforementioned upshot as the valve remaining closed, thus allowing a siphon flow.

8. If a valve fails, the consequences could be dire. I and other people have sometimes removed the valve from the loop in the engine organization (Not the head discharge) and installed a hose from the air vent in the loop to a vent overboard where a small-scale corporeality of diverted water flow tin can be easily seen when the engine is running. With this arrangement, you don't worry about the valve hanging up. The vented passage is always open up. And you can hands tell when the h2o is running and when it stops. This menstruum, all the same, must not be of such book that it adversely affects the cooling of the exhaust.

9. Flushing regular doses of vinegar through the caput will help to diminish whatever deposits.

Author

Tom Neale

Technical Editor, BoatUS Magazine

One of the summit technical experts in the marine industry, Tom Neale, BoatUS Magazine Technical Editor, has won nine first-place awards from Canoeing Writers International, and is author of the magazine's pop "Ask The Experts" column. His depth of technical knowledge comes from living aboard various boats with his family for more than thirty years, cruising far and wide, and essentially learning how to install, fix, and rebuild every organization onboard himself. A lawyer by training, for most of his career Tom has been an editor and columnist at national magazines such as Cruising Earth, PassageMaker, and Soundings. He wrote the acclaimed memoir All In The Same Boat (McGraw Hill), every bit well as Chesapeake Bay Cruising Guide, Vol. 1. These days, Tom and his wife Mel enjoy cruising their 2006 Camano 41 Chez Nous with their grandchildren.

BoatUS Mag Is A Benefit Of BoatUS Membership

Membership Benefits Include:

-

Subscription to the print version of BoatUS Magazine

-

4% back on purchases from West Marine stores or online at WestMarine.com

-

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

-

Deals on cruises, charters, car rentals, hotel stays and more…

-

All for only $25/year!

Source: https://www.boatus.com/expert-advice/expert-advice-archive/2018/april/anti-siphon-valve-basics

Posted by: lewisliviss.blogspot.com

0 Response to "How To Repair An Anti Siphon Valve"

Post a Comment